|

|

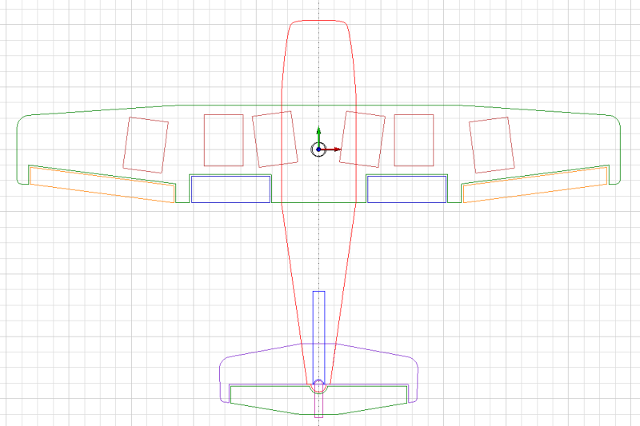

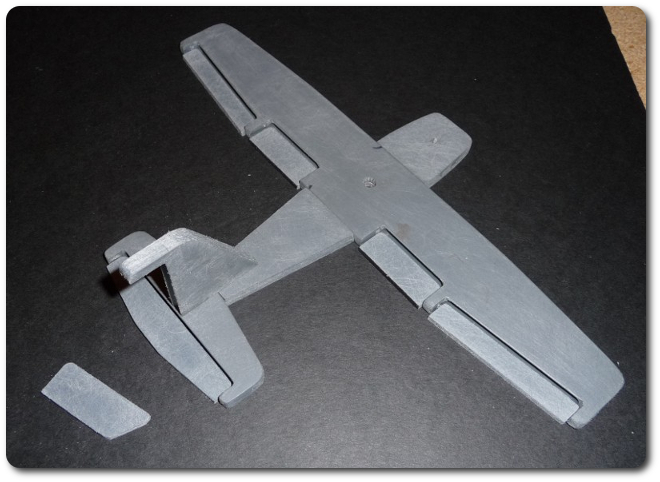

In this case, though, I have to accommodate various engineering aspects like the servos and hinges, which don't scale down nicely. Therefore, my planform is a little pudgier (actually, it's not too far off a 210).

|

|

|

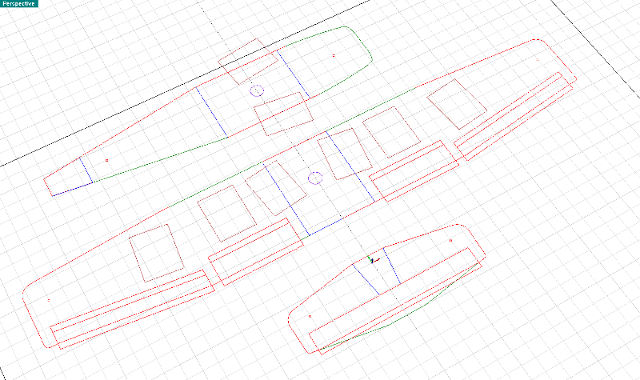

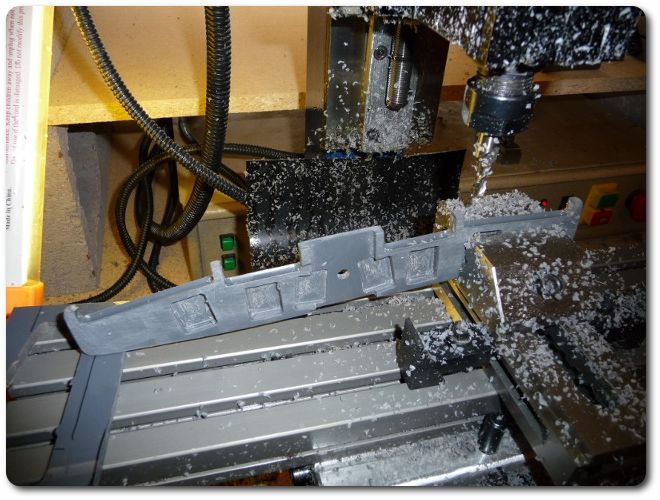

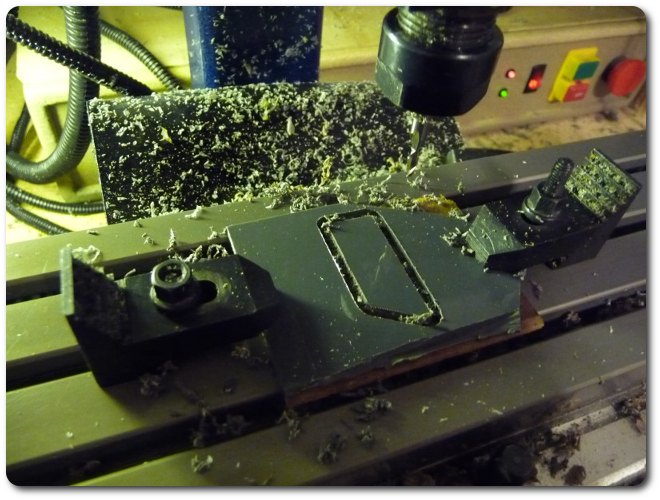

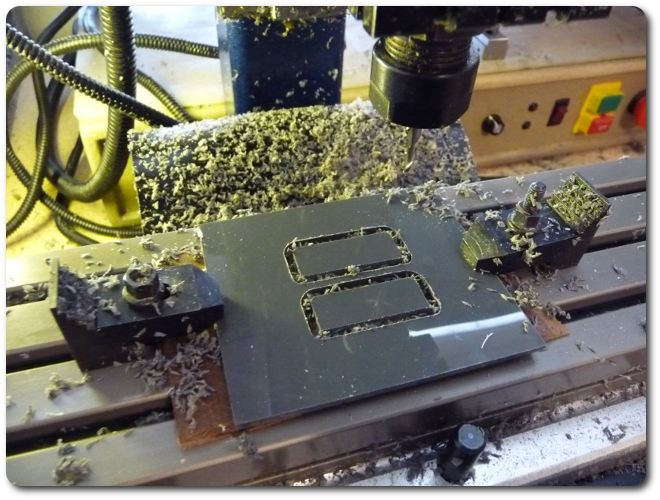

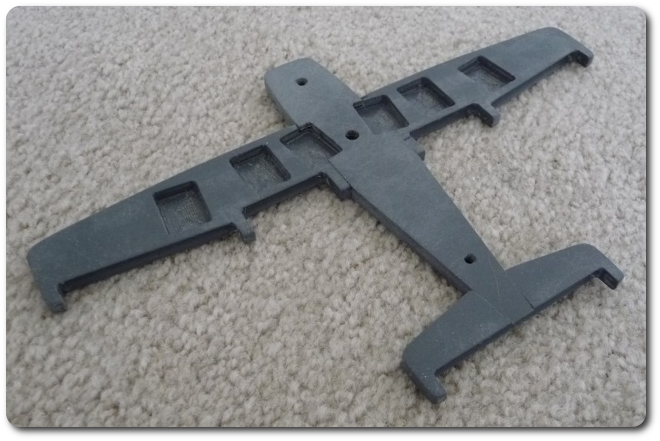

The actual layout is much more complex. The submerged part of the iceberg that students don't see is that the construction/fabrication process of any design involves countless intricate steps to get things organized in such a way that they can actually be built. (As a master's student, I was the software architect on an NSF grant for industrial engineering, and I really saw this part in action.) In this case, there are three pieces to the UAV because, among other reasons, (1) my mill isn't large enough to accommodate the entire planform as a whole, (2) the machining has to be done on both sides in a particular order, and (3) screwing up one piece shouldn't affect the others. It also saves on material, but 1/4" PVC is cheap. But this approach does complicate fabrication, especially on two sides (not to mention the edges, which are still coming). The little reference holes at the ends facilitate alignment.

|

|

|

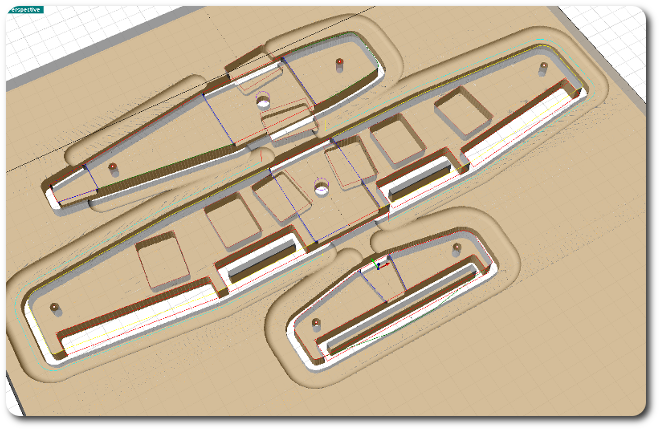

This is a collection of profiling, pocketing, facing, and drilling, plus roundover profiling of exposed edges.

|

|

|

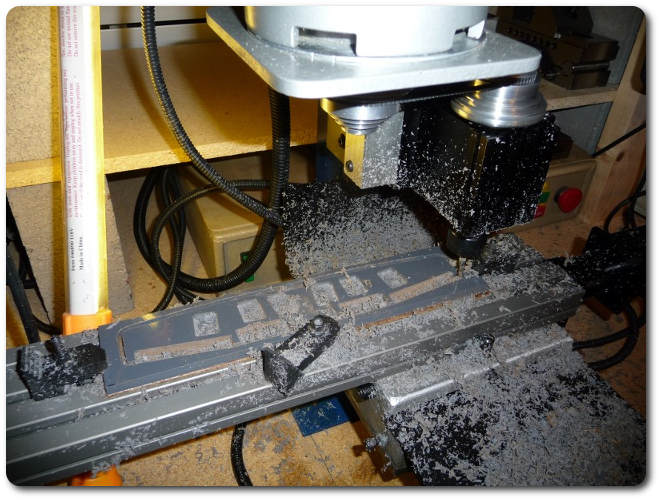

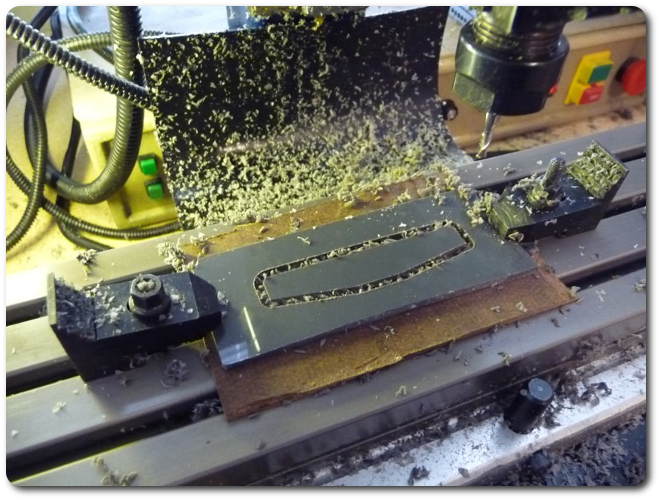

Here's cutting the underside of the wing.

|

|

|

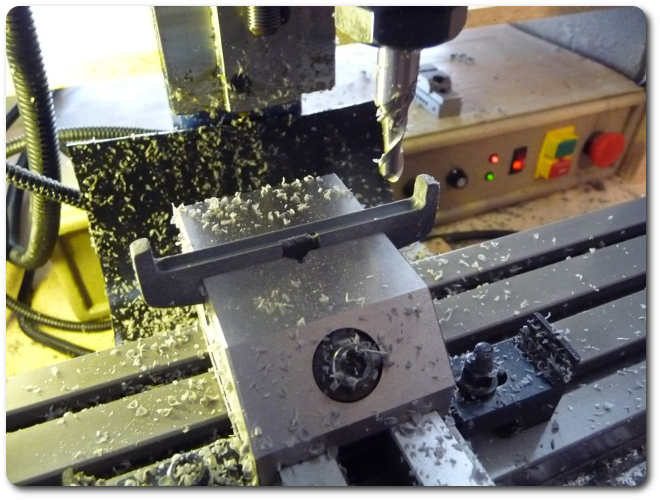

The joints for the control surfaces are carved out with a ball end mill.

|

|

|

Here's a closer look at the process on the horizontal stabilizer.

|

|

|

And this is the first version of the vertical stabilizer. It looked a little oversized when I put it on the fuselage, and I realized the rudder mount wasn't going to work well this way.

|

|

|

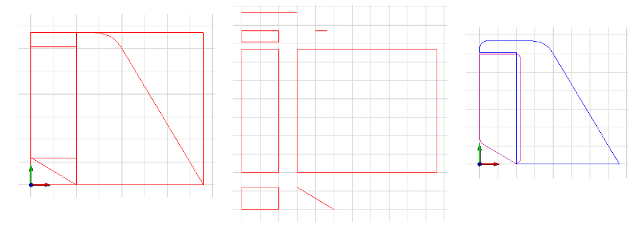

My typical approach to designing parts is to lay out a geometric framework on the left to define the points I want to connect. Stripping out the framework in the middle results in the right. (These are not quite to the same scale.).

|

|

|

The fuselage is 1/4" PVC, and the control surfaces, like the rudder here, are 3/16".

|

|

|

Here are the flaps.

|

|

|

And the ailerons.

|

|

|

And finally the elevator.

|

|

|

Here's how it looks at this point.

|

|

|

|

It's time to pull out the options for the hinges. This is carbon fiber, fiberglass, and metal rod and tube in every possible diameter.

|

|

|