Fence and Corral Miscellany

|

| This is another fabrication project that demonstrates multidisciplinary engineering. It's a simple metal fence to separate parts of my parents' property, including the corral. |

|

|

|

Kahlua, the horse, had knocked down most of the brick wall in the back yard a few years ago. It wasn't much of an issue until our dogs went to live there temporarily while all these moves got straightened out. In an effort to keep them in the inner yard, we piled up a bunch of junk to block the hole. Some of the "junk" was actually parts of a nice metal fence and gate we used to have, but it was now basically scrap. For the holidays, I decided to make a real fence.

|

|

|

|

One of the segments was being used as a gate in the corral. Unfortunately, the two free segments had different diameter square tubing, so making the fence out of them would have looked a little odd. What I really needed was this gate segment (left) and its mate (right).

|

|

|

Engineering field work can sometimes be unusual.

|

|

|

Since the bases were rusting out anyway, I decided to cut up all three and rebuild them out of the salvagable parts. This allowed me to swap the square tubing, too.

|

|

|

|

But first I had to put a new blade in the bandsaw, which had broken during another project. I had to bring a boatload of equipment home for the holidays to do this project.

|

|

|

Trimming off the ends left nice metal to work with. Some of these pieces are bent, but they're only 1/16"-wall square tubing and easy to realign.

|

|

|

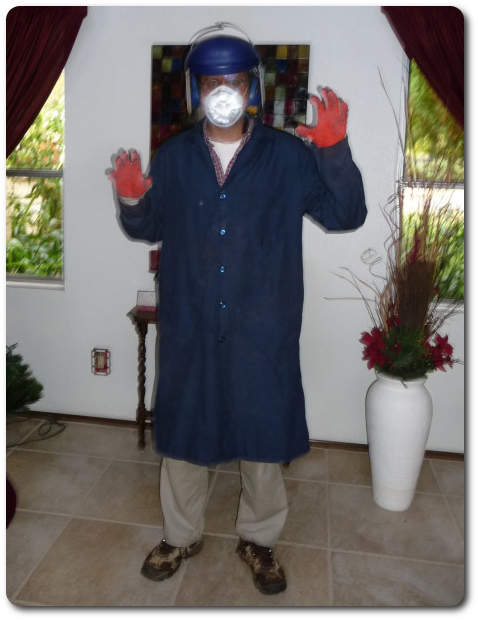

There's lots of cutting, grinding, and sanding at this stage. Even though it was December, I was in full Halloween attire.

|

|

|

But letting sparks fly, as in this video, is therapeutic, especially after the hellacious semester I had just wrapped up.

|

(video 7 MB)

|

|

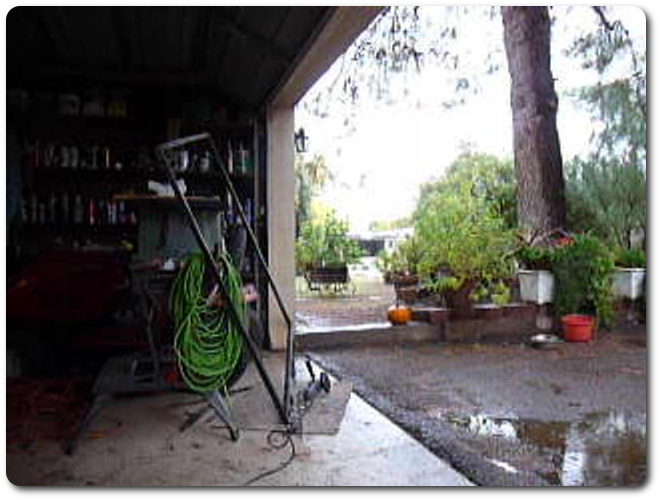

The problem with all this safety gear (which I wear religiously) is that it was raining nonstop in Phoenix. My goggles would fog up in under a minute because of the humidity. Everything was such a sloppy mess.

|

|

|

But it's coming together. Here are the weldable surfaces, which were cleaned up with a 40-grit flap disc.

|

|

|

And here are all the parts after one afternoon. I couldn't go further because going out in the deluge to measure the fence opening wasn't an option. Plus I needed to get a couple pieces of 1" square tubing for the top and bottom of the fence. Other than that, everything is recycled, and there's almost no waste (or cost).

|

|

|

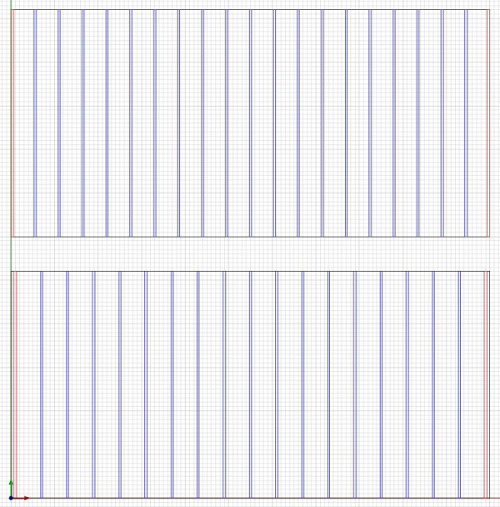

No, an actual CAD drawing isn't necessary, but it was convenient to determine the spacing of the bars. The top variant has 5.5" spacing, the bottom 6". I went with the bottom because none of the dogs are that narrow. Especially not after mom's been overfeeding them...

|

|

|

First up was getting power to the welder. I had to tap into the range, which required me to build an adapter, which later turned into a permanent version with the power-adapter project.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44