Fence and Corral Miscellany

|

|

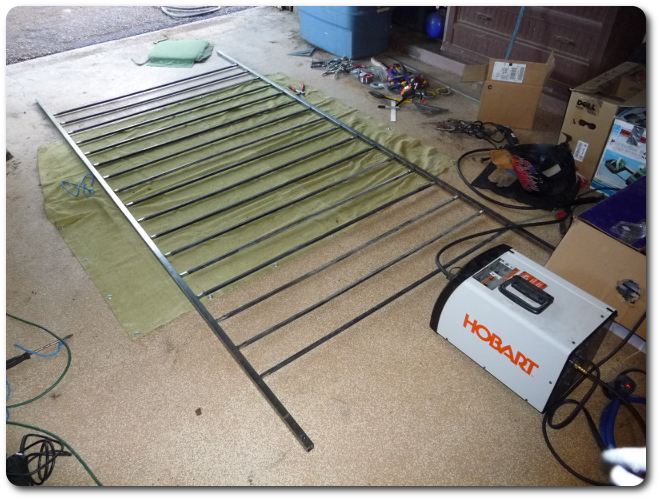

After a quick trip to local metal supplier, it was time to lay out the frame.

|

|

|

And here it is all tack-welded.

|

|

|

And welded up and ground down. The original metal was disgusting because it had been out in the corral for so long. This took some scrubbing before priming and painting.

|

|

|

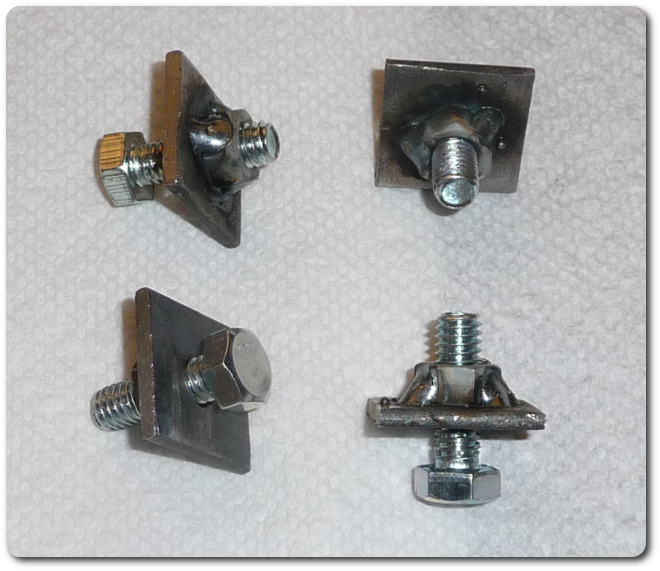

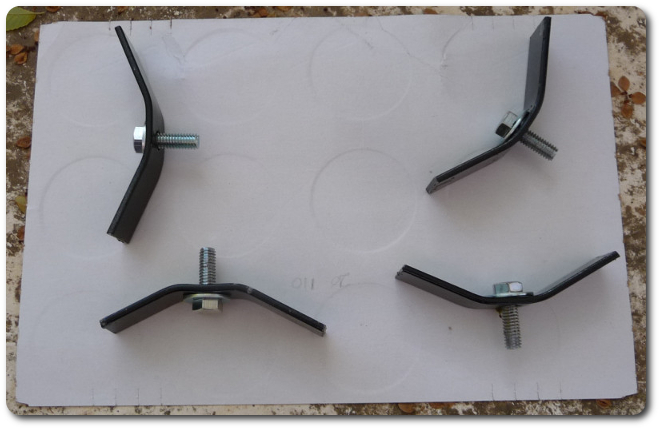

The end mounts are weld nuts. I didn't need much beyond a solid tack weld here because these are under compression. The tool bench was a different story with its levelers last year.

|

|

|

|

The butterfly mounts attach to the end mounts and squeeze the channel in the block wall.

|

|

|

|

Even though I did a lot of these welds in the dark, they turned out quite nice. This is 0.65" thin-wall steel tubing not in the greatest condition. In quite a few places, I had to build up the welds to bridge gaps. The welds are stronger than the tubing itself now.

|

|

|

|

And here it is. Total cost: $67, half for the 20 feet of 1" square tubing on the top and bottom, and the other half for paint (which is shared with the last part now).

|

|

|

|

And yes, I was camping with my dogs back there, at least until the tent got drenched. I need to get a picture of Amigo, the friendlier, inquisitive llama, and the dogs rubbing noses.

|

|

|

|

The last part was to rebuild the corral gate, which I had gutted for its uprights. This was some nasty rusted metal.

|

|

|

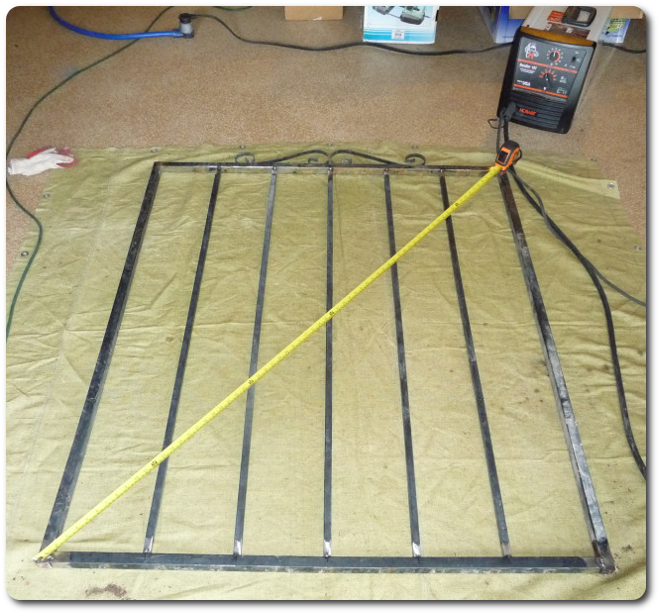

Here's the old geometry trick in action to verify that the frame is square. Both diagonals must be the same length.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44