Mini-Lathe

|

| This project was to build a drive and control system for a small lathe in support of other projects. The Taig lathe isn't especially large compared to the big stuff I have access to, but it's wonderful for small engineering work. Plus it has a ton of accessories, and it's relatively easy to make specialized ones. |

|

|

|

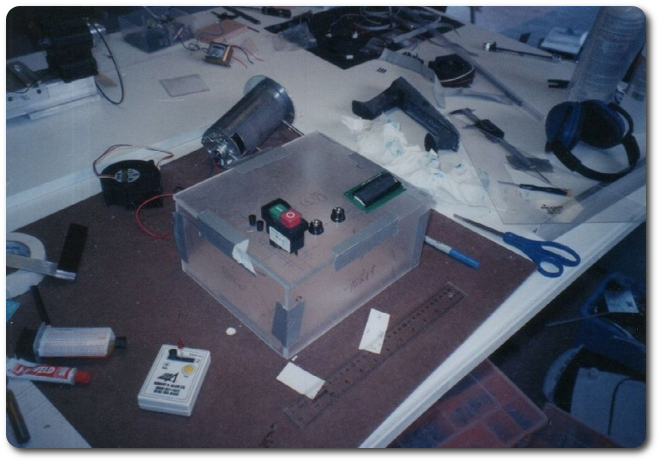

Laying out the interface.

|

|

|

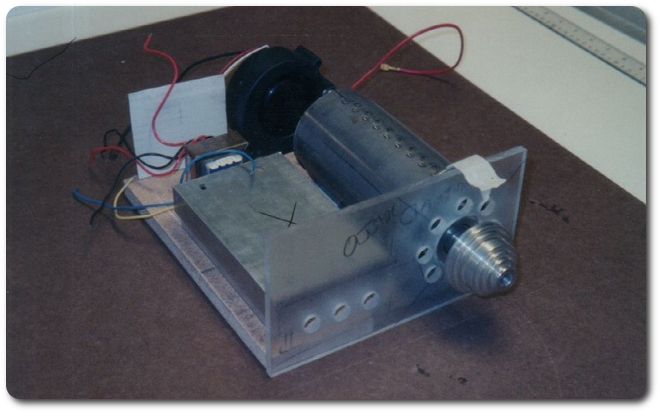

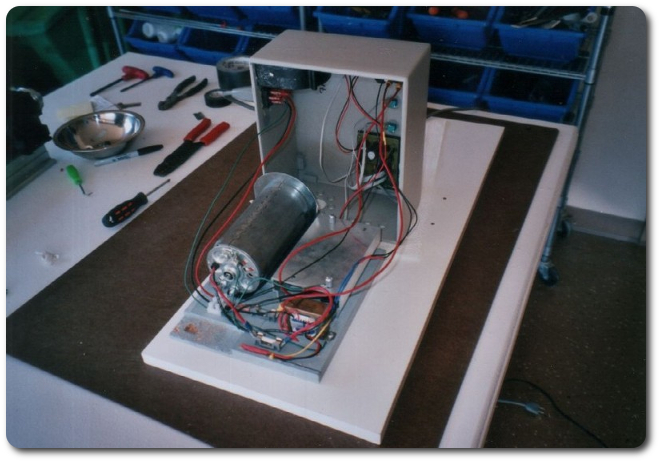

Test-fitting the innards.

|

|

|

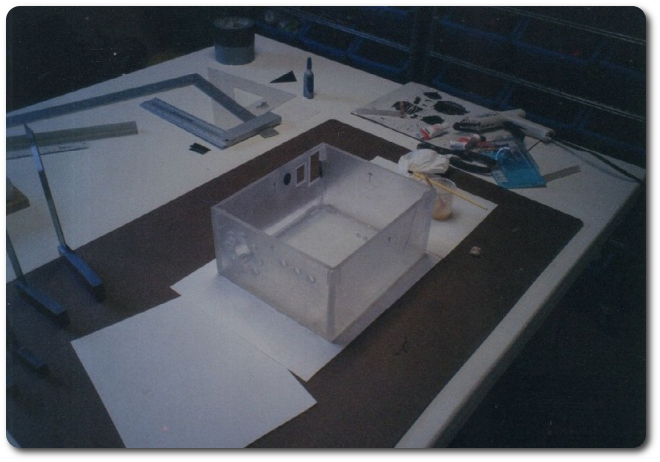

Glue action. The 1/4" plexiglass is actually a cracked 4x4-foot chair runner from my office.

|

|

|

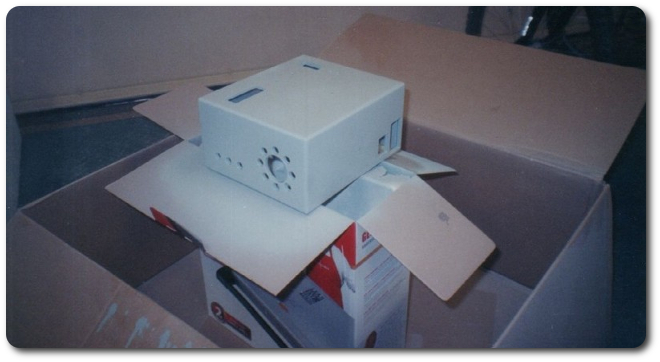

Painting and sealing. The finish has to be impervious to all the solvents that fly around while machining.

|

|

|

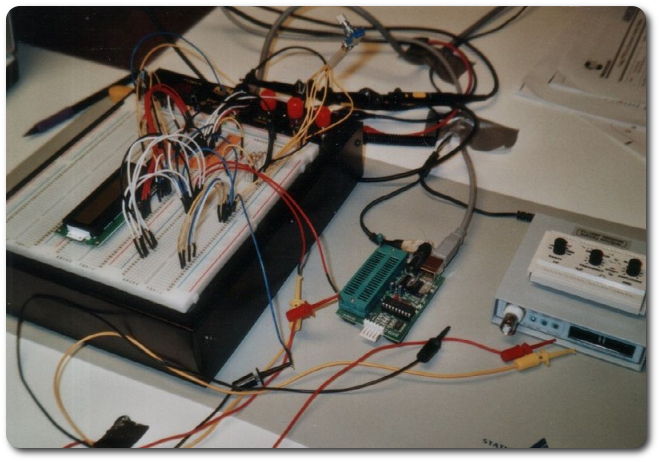

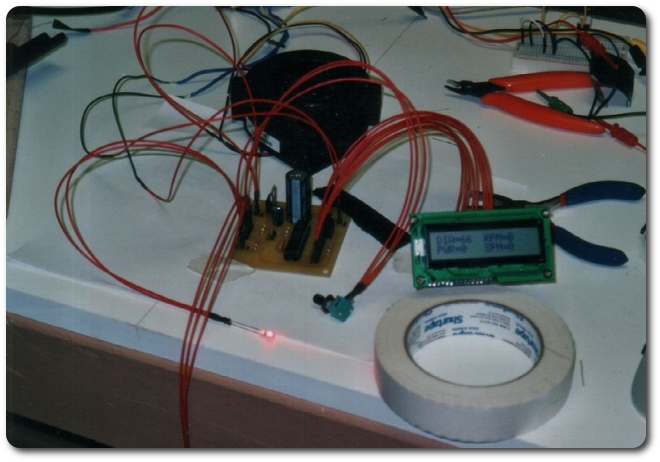

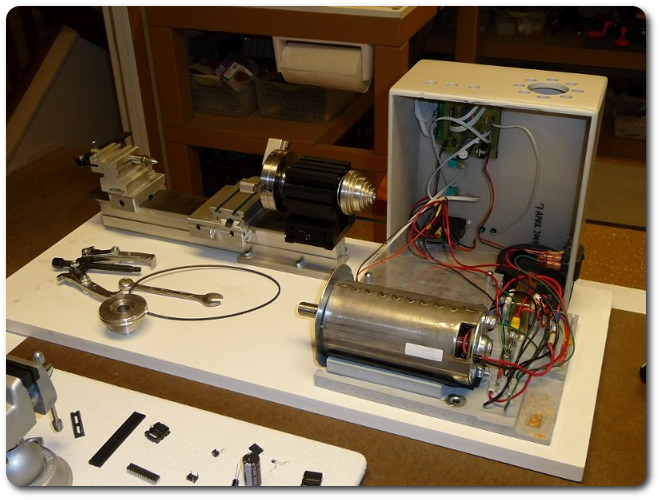

Prototyping the controller. It's pretty simple, unlike for the mill. This machine is entirely manual. It's not practical to convert it to computer control because of the nature of the work I do with it.

|

|

|

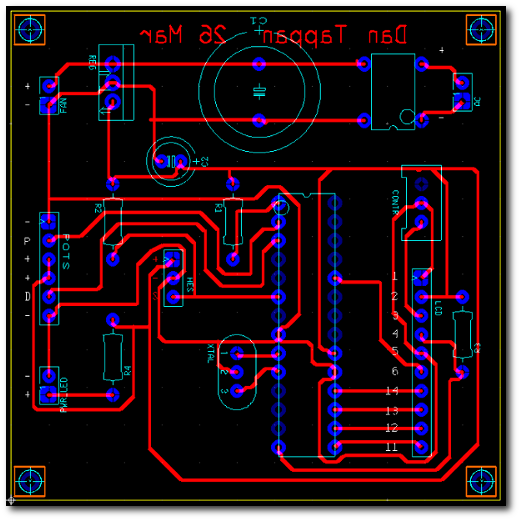

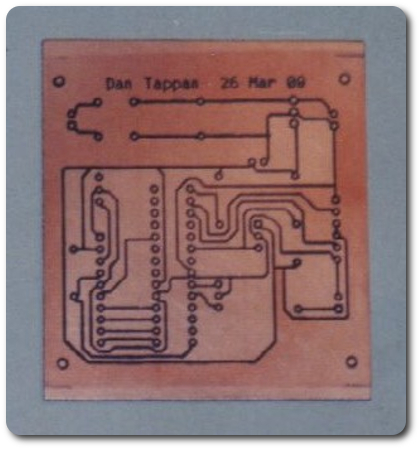

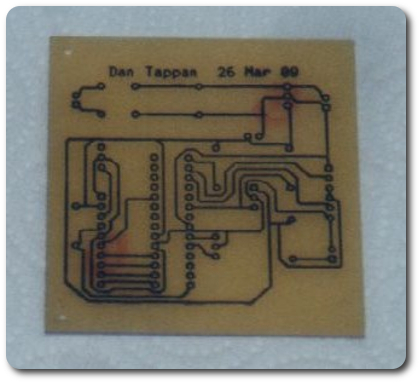

The circuit layout.

|

|

|

|

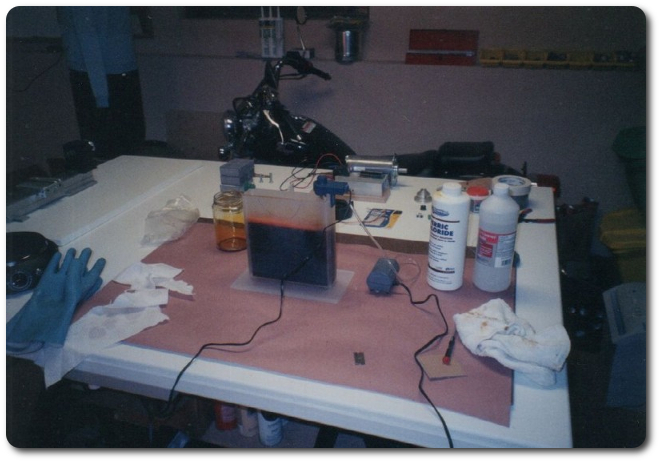

Etching with my cute little tank that looks, hmm, suspiciously like the same plexiglass. The heater, thermometer, bubbler, and pump are all for fish tanks .

|

|

|

|

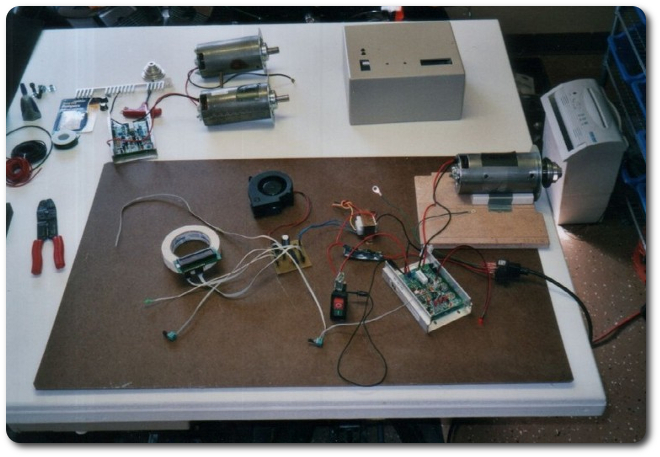

Testing and wiring it up.

|

|

|

|

And final assembly.

|

|

|

|

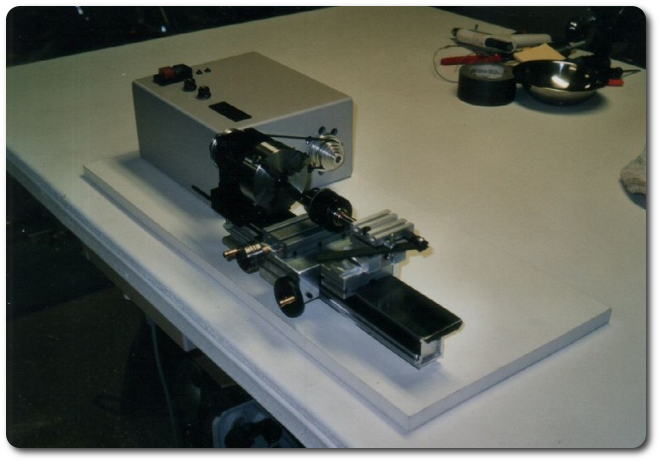

All done with the first version.

|

|

|

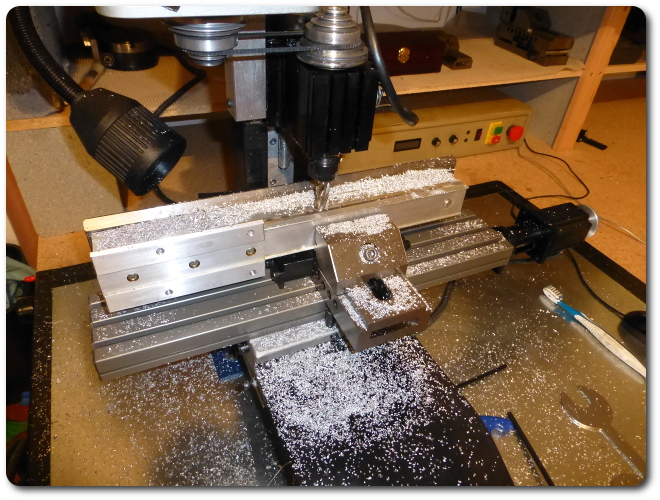

Later Taig came out with a power-feed mechanism that I retrofitted. This entailed machining the original bed to make room for the new parts.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44