|

|

|

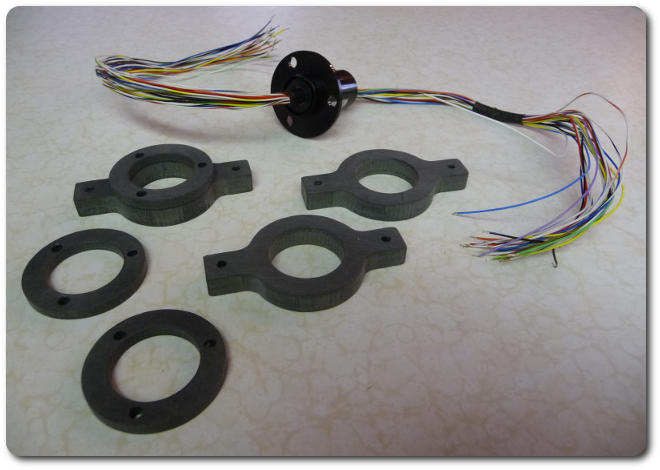

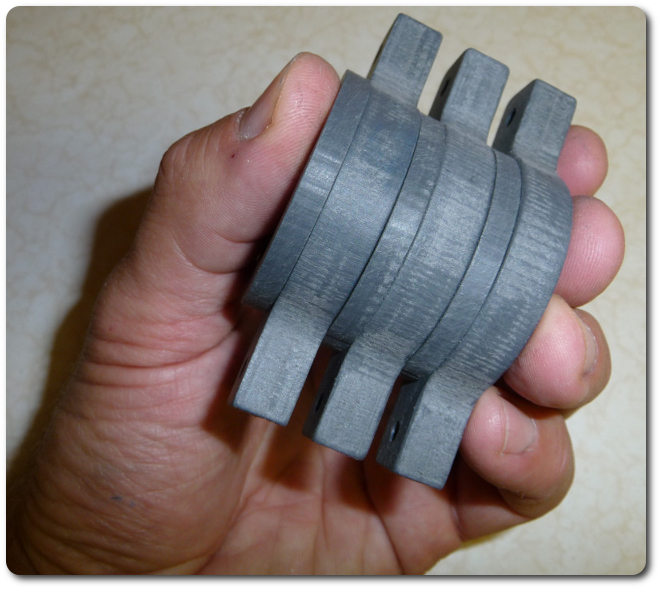

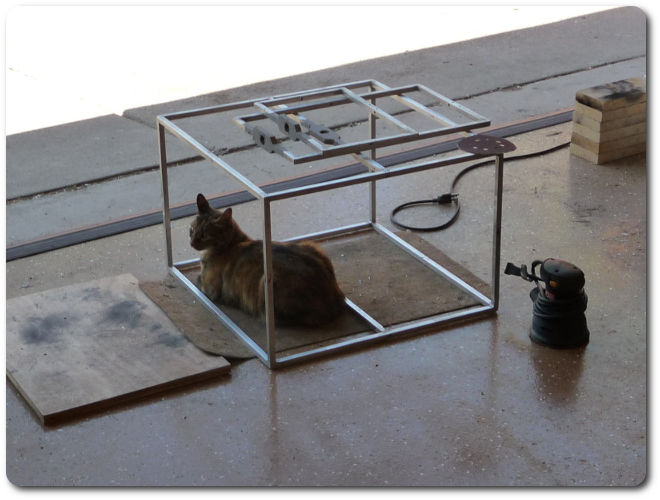

If this project doesn't work out, I guess I can build a dinosaur skeleton!.

|

|

|

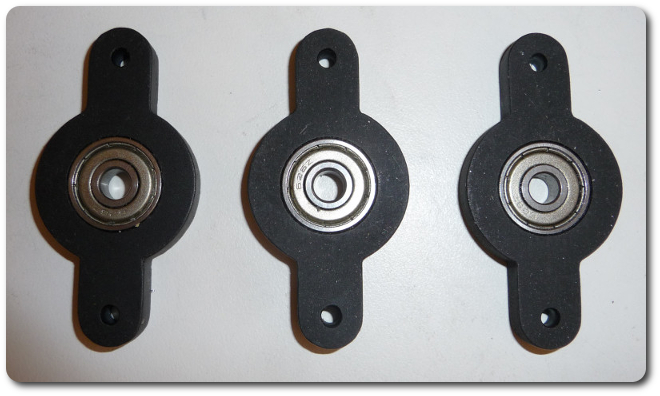

Now it's time for bearings. I have countless assortment and sampler sets of common goodies to make the hands-on part of construction (and design, actually) easier. When I know what works, I order the actual quantities I need.

|

|

|

And here's the result. The mount rings are 1/4" PVC, which isn't especially strong, but for the light forces exerted by the shafts, it doesn't matter. (No, I didn't do any formal engineering analysis to prove this.).

|

|

|

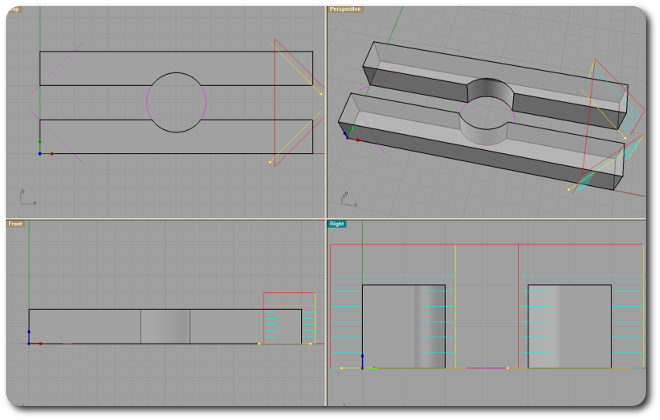

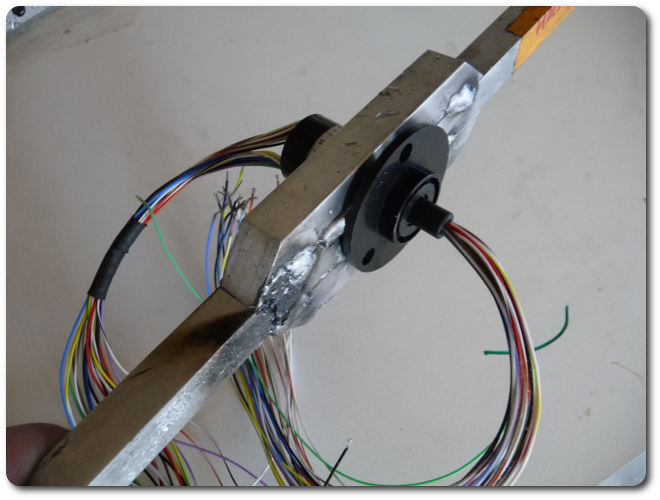

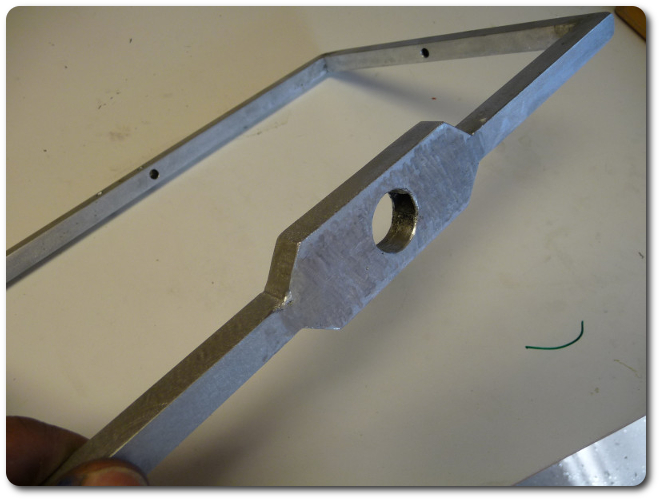

Now it's time to go back to the frame. The 1/2" square tubing of the frame is way too small to accommodate the slip rings, so I need to widen the frame at points with 1/2" solid squares.

|

|

|

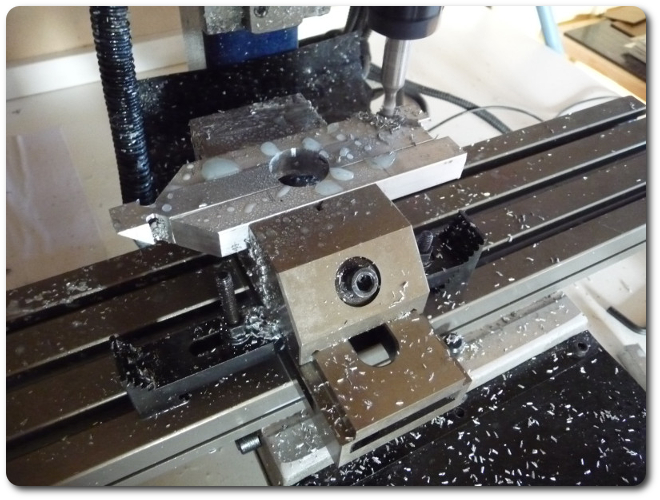

The center piece is sacrificial. I don't consider myself a machinist in any formal respect because those folks have earned their title, but I do recognize and use a lot of the tricks that I see make professionals professional. In fact, our own ISU College of Engineering machinist said I'm welcome any time in his shop. Machinists are a territorial bunch, which makes this a great compliment.

|

|

|

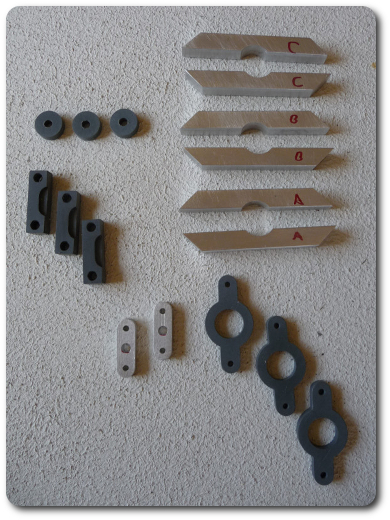

Parts is parts, and we've got a bunch at this point.

|

|

|

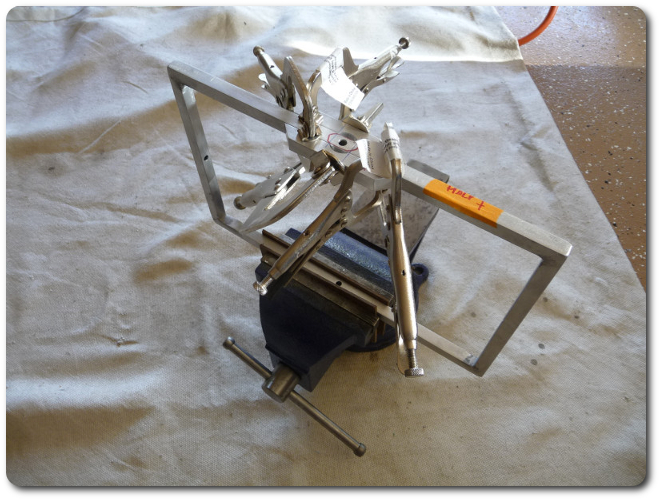

On this week's episode of Attack of the Clamps, it's time to weld those extender flanges to the frame. This is particularily tricky because the flanges are solid, but the frame is hollow. These have substantially different thermal characteristics when welded, and the hollow component is at risk.

|

|

|

And it knows it's at risk, too, because I'm going in for the kill...

|

|

|

The extender flanges were precision milled to the final size, but the frame still needs its part of the hole. Gargantuan Silver and Deming bits are great for this. All this did is clear out the leftover junk in the hole.

|

|

|

Tack welds aren't supposed to be pretty; they just need to hold things together long enough to do the final welds. In this case, my fears of injuring the frame were not realized.

|

|

|

And as a reality check before final welding, let's make sure the slip ring fits.

|

|

|

And here's the completed extension after cleaning up the final welds (which I don't have a picture of).

|

|

|

Kalakia, my adopted stray cat for the summer, is earning her food by inspecting my work.

|

|

|

Luckily she doesn't know what its secondary use is!.

|

|

|