Mechatronic Violin-Bow Testbed

|

|

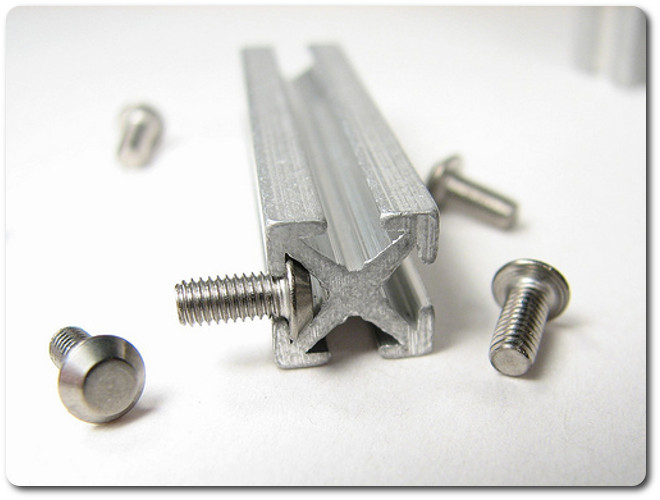

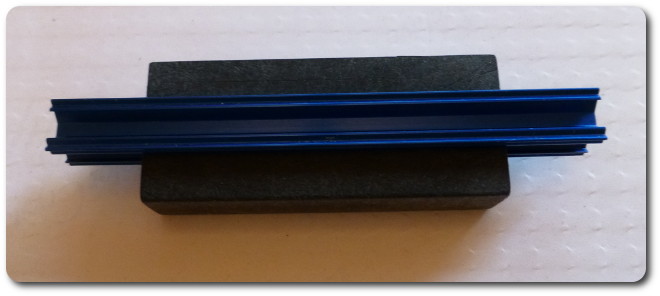

Now on to the mechanical aspects. The "bow" is a 1x1x40-centimeter extruded aluminum beam from MicroRAX.

|

|

|

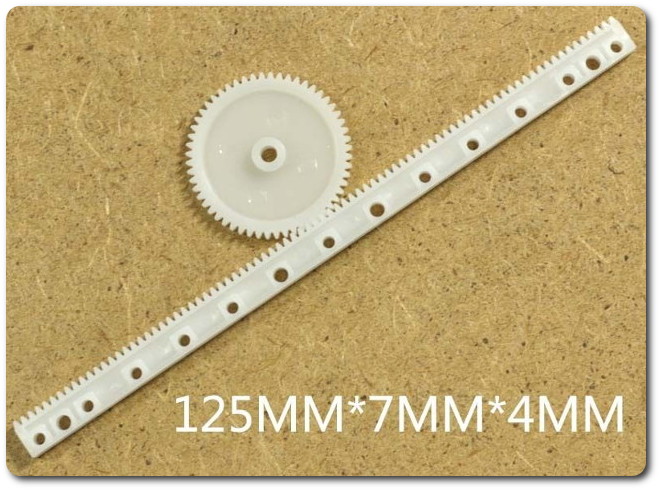

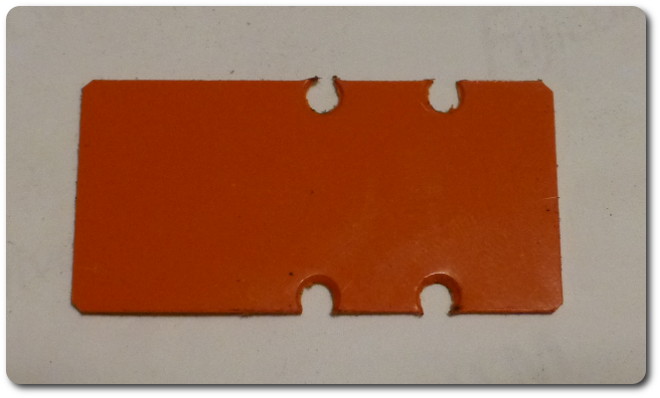

The rack in the rack-and-pinion drive is some el-cheapo plastic pieces from China.

|

|

|

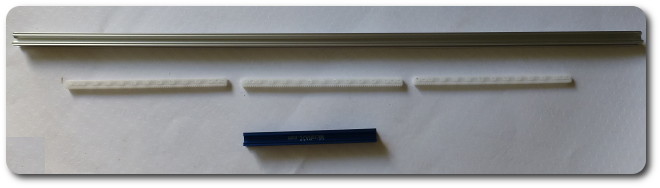

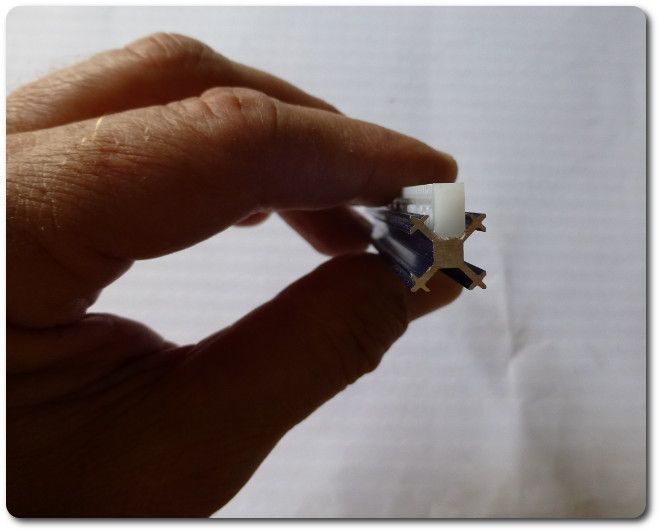

It wasn't clear how these would attach. I considered fabricating all sorts of fancy mechanical connections, but ultimately the simplest approach was the solution: epoxy.

|

|

|

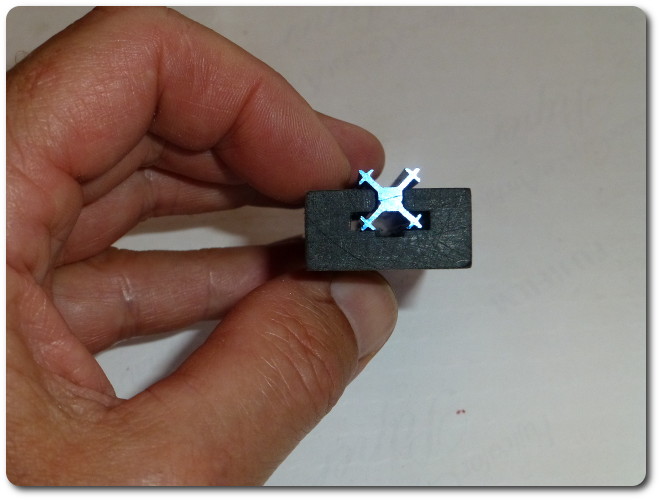

They needed a little modification to fit snuggly. Conveniently, the edge of the beam is really sharp and shaved the plastic easily to form. They were bonded in this position.

|

|

|

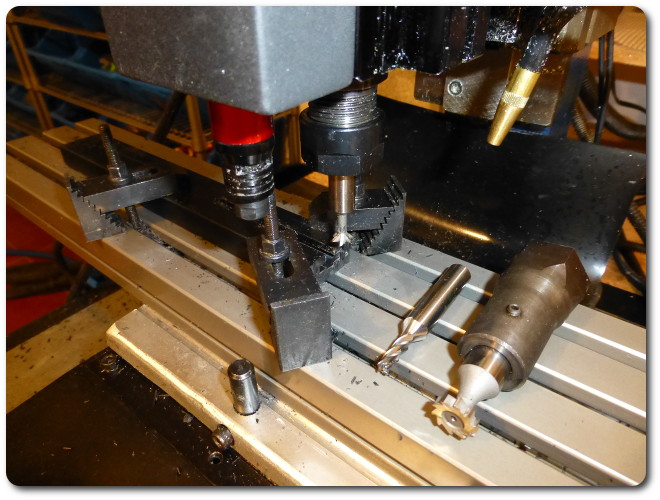

The slide mechanism was another unknown. I considered ball bearings and all sorts of nifty approaches, but in the end, again the simplest won out. It's a channel carved out of a self-lubricating plastic block. First it was slotted with the middle bit, then with a Woodruff-key channel cutter (rightmost bit), and finally angled with the mounted bit.

|

|

|

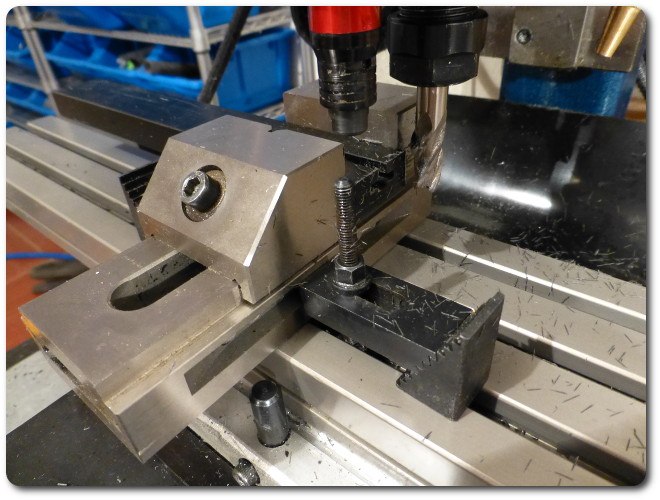

Then it was squared off. All of this was done manually on the mill, no CNC programming at all. I adjusted the measurements as I went. Everything on this page happened in one day, so a lot was done in an ad hoc manner.

|

|

|

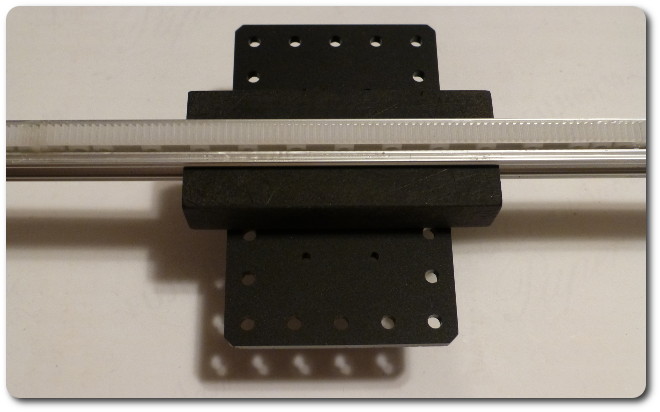

Here's a smaller box rail in place to check the fitting: nice and snug.

|

|

|

|

The mounting screws and a cutout to accommodate other screws were also done manually.

|

|

|

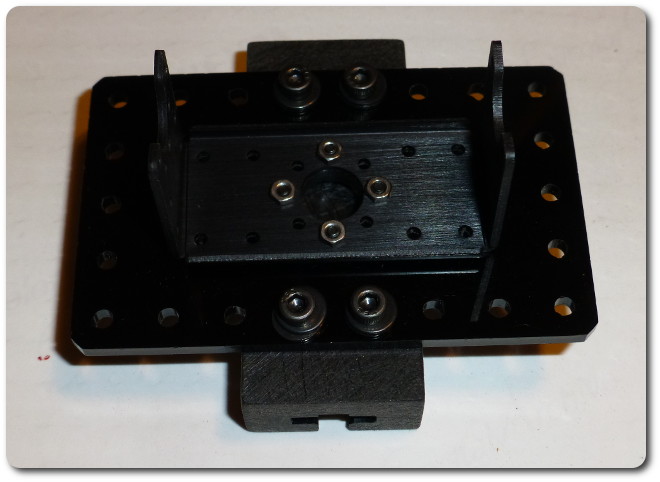

Attached to the turret platform (upside down), it looks like this.

|

|

|

Despite the ad hoc fabrication, there's very little friction, play, or backlash. Overall, the entire turret assembly has some slop in it, which could be reduced, but for most purposes, it's fine.

|

|

|

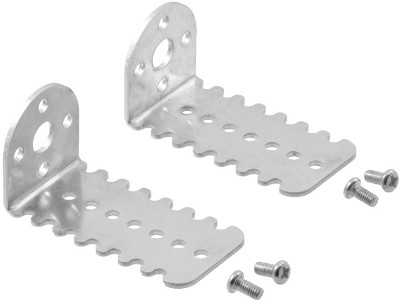

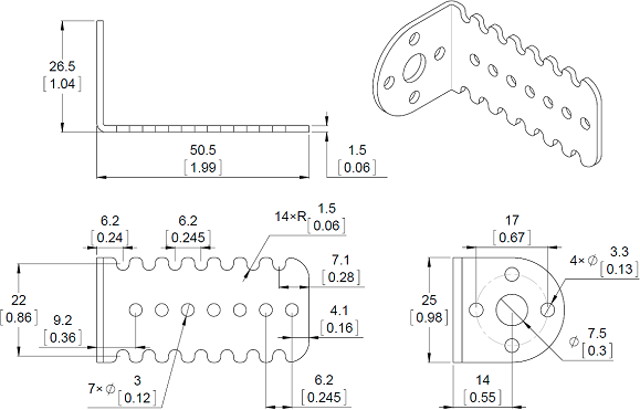

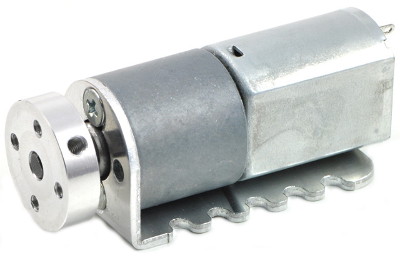

The motor mount was another make/buy dilemma.

|

|

|

It was further complicated by the availability of the plans, but it was admittedly worthwhile to spend the $7.45 and buy the mount.

|

|

|

It was the same story with the shaft hub: trivial to fabricate, but even more trivial to order.

|

|

|

The final result was this guy, minus the pinion gear.

|

|

|

But consistent with the ad hoc nature of this project, the alignment of the motor with respect to the rack and pinion had to be determined experimentally. For this, a simple piece of plastic shim did the job.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44