AquaDog Hydrotherapy Tank

|

|

|

|

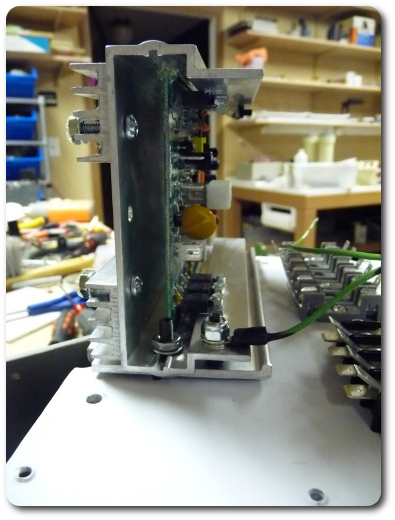

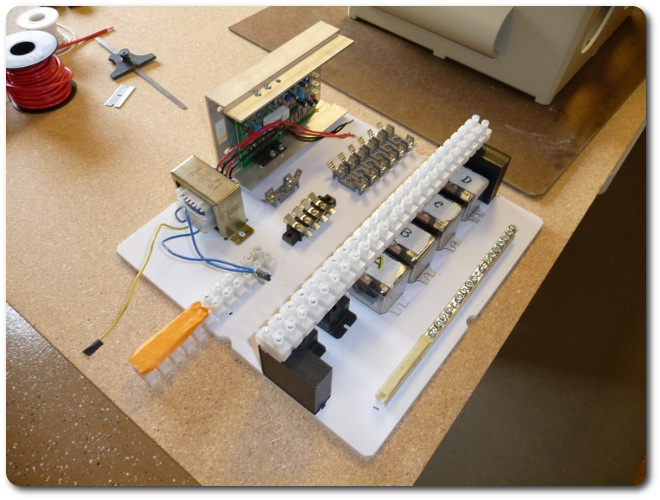

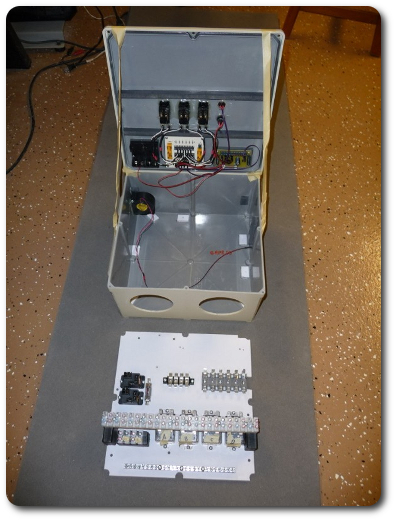

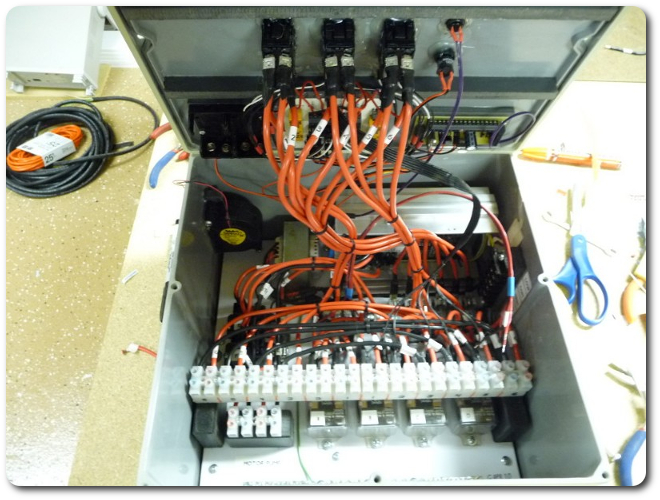

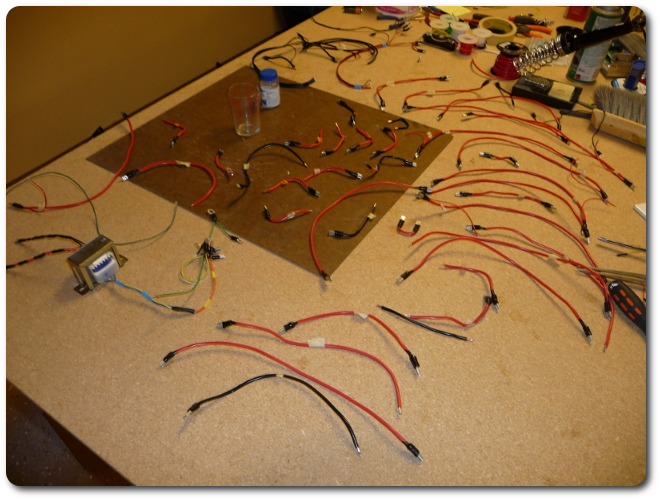

Back to assembling the power box.

|

|

|

|

|

Nifty sealing on the wires.

|

|

|

|

|

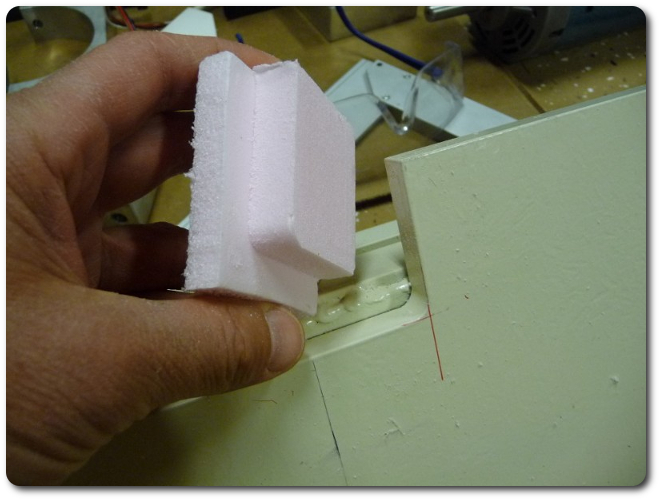

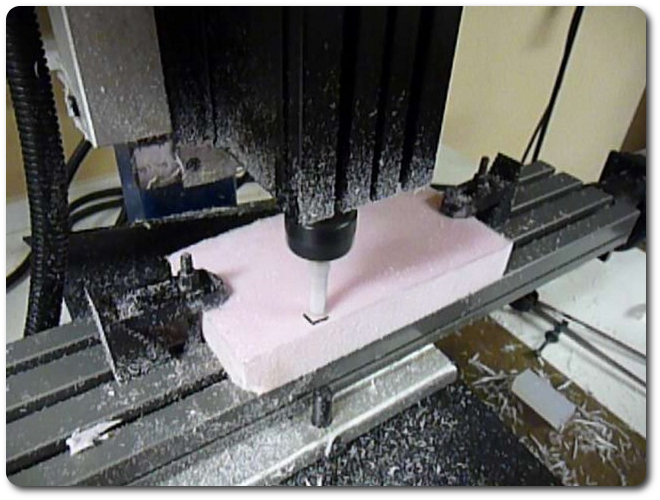

Back to working on the drive mechanism. The base plate was cut early in the process, well before we knew how everything would assemble (there's a lot of ad hoc engineering here), and the enclosure I'm putting over it needs to fill this gap. Foam prototypes are awesome because they're cheap, easy, and fast to machine.

|

|

(video 6 MB)

|

|

|

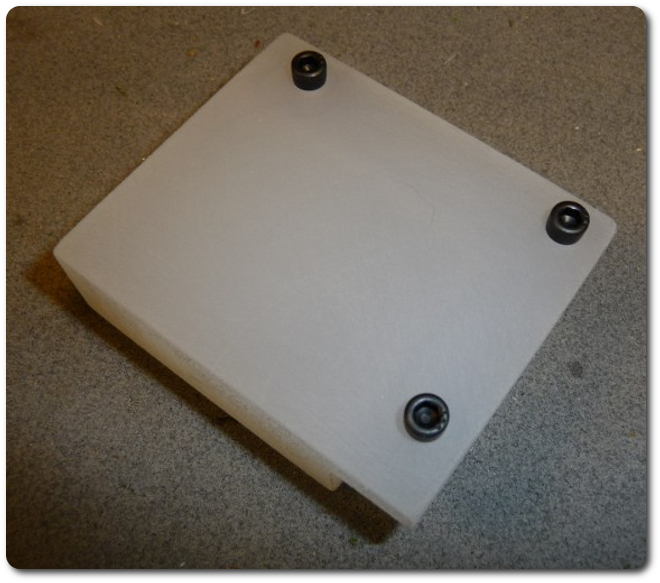

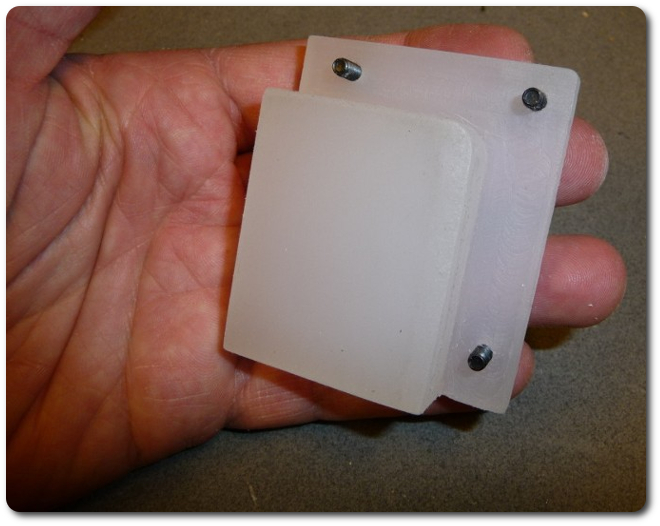

My first experience with polypropylene. It makes a huge mess with fused chips and swarf, but the stuff is really strong.

|

|

|

|

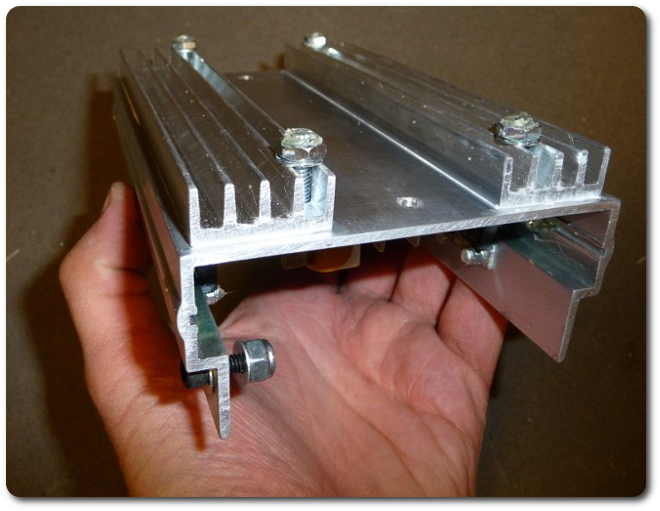

Really strong, as in when it gummed up, it actually stalled the drive motor and blew the fuse in my controller. But this is a good opportunity to show reusability in engineering design. The treadmill mill controller, muffin fan, transformer, and a lot of various unseen smaller parts from the mill are the very same ones I chose for AquaDog.

|

|

|

|

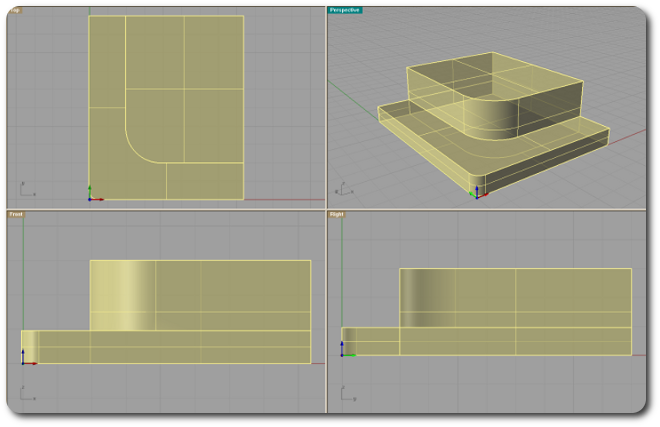

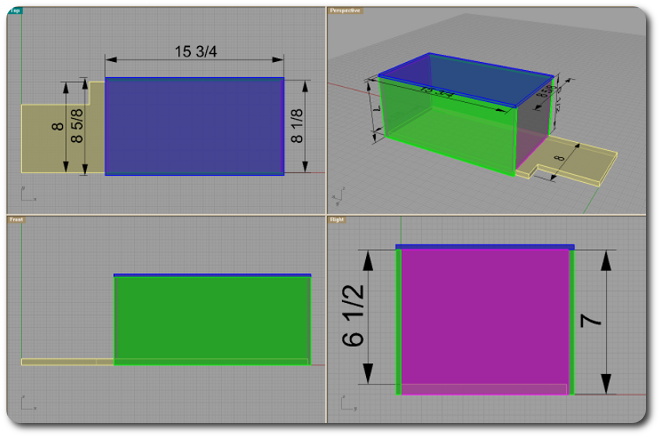

Building the water-resistant enclosure. The CAD drawing is for reference only, not for automated machining.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44