|

|

As a follow-up to above: the electrician responsible for this shoddy work had to redo it, and boy, was he mad. He claimed (1) it was all my fault, and (2) it was no big deal. The kicker: two of his eight repairs still failed my inspection!.

|

|

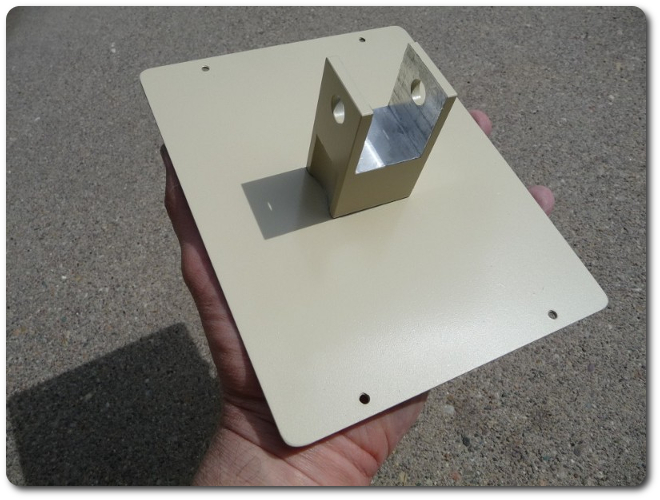

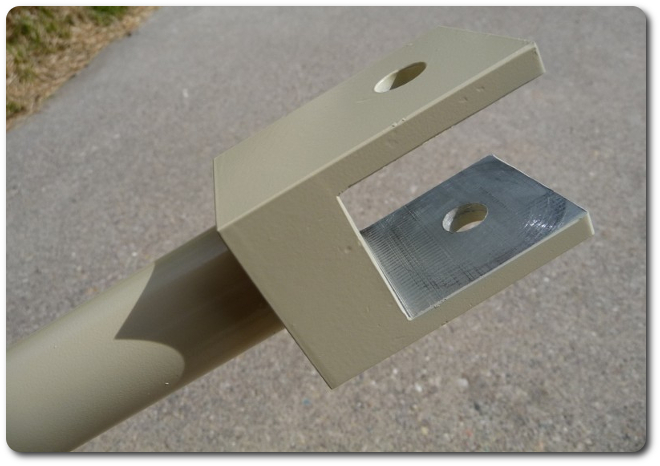

Engineering is about solving problems, but some like this one are annoying and avoidable. This is 1/2" mild steel plate with welded channel iron underneath, as it came from the machine shop — not fun to mount on the mill to square it up, especially after powder coating. They must have grabbed a piece of scrap without measuring it.

|

|

|

|

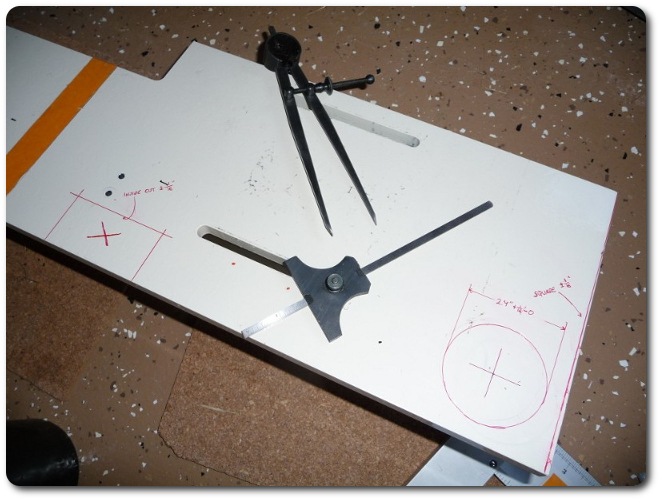

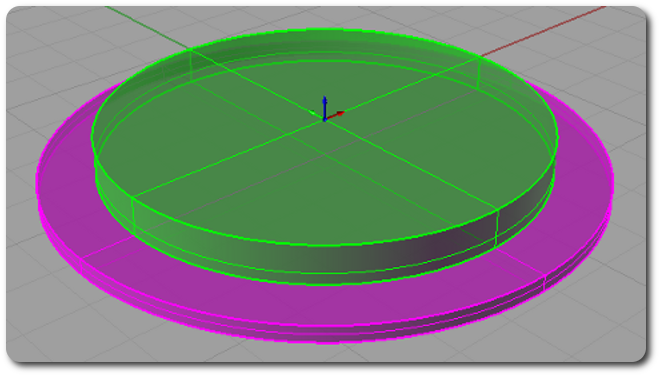

Here's the solution, along with some other layout markers for the cooling system. My mill table can't handle the size and weight of this piece, so our ISU College of Engineering machinist, Miles Whiting, did it in the college shop to my specs.

|

|

|

|

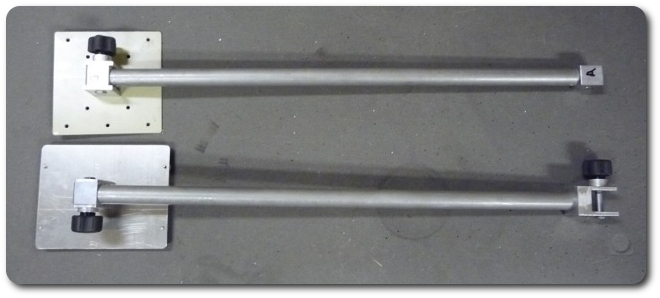

Here's more of Miles' excellent and much-appreciated work: a swing arm for the user control box.

|

|

|

|

|

|

|

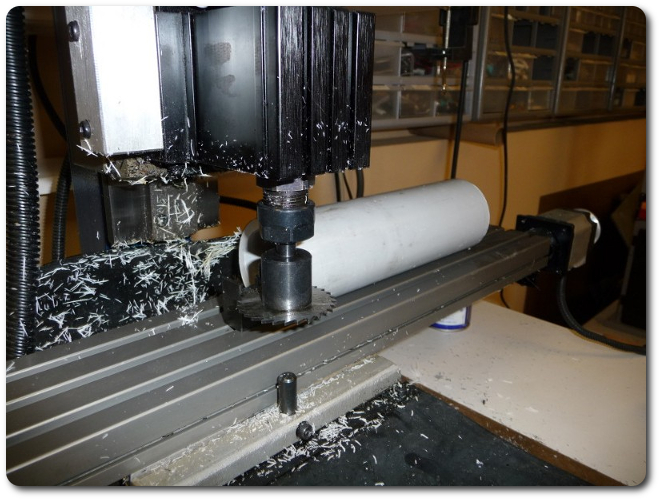

Making the cooling exhaust on the power box with a really scary cutoff blade.

|

|

|

|

|

|

Due to some design decisions that I didn't end up needing, there was a hole in the power box.

|

|

|

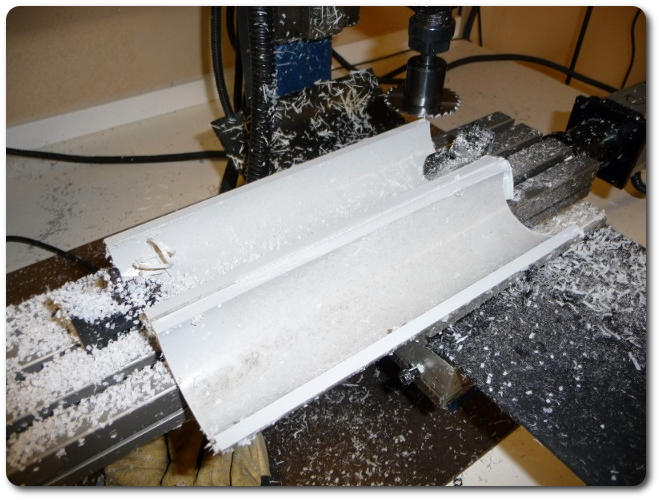

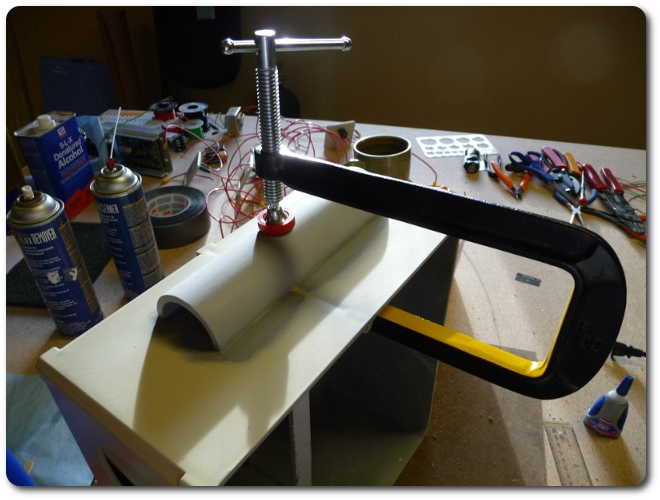

So here's the simple solution: a nice little CNC'd PVC plug.

|

|

|