Tool Bench

|

|

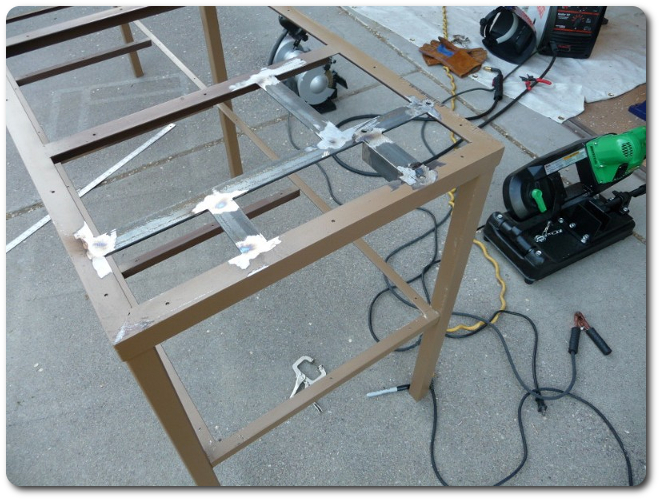

MIG welding the butt joints with 0.35" solid-core wire (no flux) and 75% argon, 25% CO2 at 20 cubic feet per hour at about 22 volts, 90 amps, and a feed rate of about 360 inches per minute. Since most of these welds were hidden, I experimented a lot with various settings, some more successful than others. (Note the dog hair — everywhere in the house).

|

|

|

|

Apparently I can't weld straight, but it doesn't make any difference. This one has far better penetration than the one above, but it's probably weaker because of the misalignment.

|

|

|

Grinding.

|

|

|

|

Light sandblasting. I did the visible surfaces only.

|

|

|

Primed.

|

|

|

Visible surfaces painted (not that you can tell). Conveniently I can overspray onto the wood chips all I want without any drop cloth because the colors are the same (and the dogs churn them up frequently).

|

|

|

|

|

|

|

I decided the vise and anvil go better on the left side, so I had to add supports over there.

|

|

|

All done, including a 4' power strip that's not visible underneath. The particle boards behind the bench are from the divider-cabinet project that was being neglected.

|

|

|

And occupied. Not bad for a few days and about $100.

|

|

|

© 2025 Dan Tappan and Eastern Washington University

— last updated 9 Apr 2025 15:44